Aluminum has been the principal material used in aircraft and aerospace construction for over 60 years. With the growing interest to construct more efficient aircraft, manufacturers are designing more components out of light-weight composite materials.

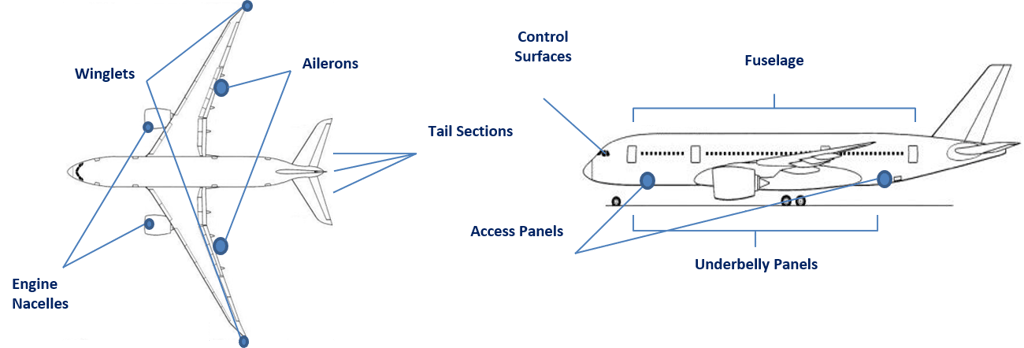

Current composite structures include engine nacelles, flaps, wing tips, and even rotary blades on helicopters and wind turbines. Composites, however, are poor conductors of electrical current. Without proper protection, they are susceptible to severe damage in the event of a lightning strike. When Dexmet expanded aluminum and copper MicroGrid materials are incorporated into the surface of these composite structures, the lightning strike energy is dissipated over the surface of the component, which prevents damage to the composite material below.

For Wind Blade applications, as with all rotary blades, lightning is more prone to hit the leading edge and the outer blade surfaces towards the tips where the highest amount of static energy is generated. For these locations, the heavier, more conductive materials are utilized. As you move towards the root of the blade, a lighter weight material can be incorporated to reduce weight and cost. The variability with Dexmet’s expanding process provides the capability of producing a custom material based on desired weight, conductivity, or open area to meet exact application requirements.

For aircraft, carbon-fiber turbine blades, and other composite-based structures

Dexmet materials are configured to exceed lightning protection standards and verification test methods when implemented in aircraft surfaces and components. All configurations minimize weight while maximizing conductivity.

Dexmet has configured new, more conductive materials to satisfy the new criteria for lightning protection on wide blades and generator nacelles.

Our expanded material is used to protect residential gas lines, marine and land-based masts, and other high value structures.

How MicroGrid® Expanded Metal Foils Keep Composite Aircraft Safe From Lighting Strikes

MicroGrid® precision expanded metal foils from Dexmet are the materials of choice for lightning strike protection in composite aircraft structures. Dexmet is the exclusive supplier for Boeing, principle supplier for Embraer, and preferred vendor to a majority of aircraft manufactures around the world.

Dexmet’s ability to tightly control the manufacturing process to meet a specific weight, open area, and conductivity requirement. This allows Engineers the option of varying materials according to specific strike zones on the aircraft, minimizing the overall weight. Our common materials have the ability to withstand a Zone 1A strike of 200,000 amps.

Download and learn why lightning Strike protection is needed on

As the power output requirements increase for wind turbines, wind generator manufacturers are moving towards larger blades to rotate these larger turbines at lower wind speeds. As the wind blades increase to over 45 meters in length, blade construction is moving away from the more traditional all fiberglass construction to utilize more carbon fiber. The carbon fiber provides a substantial weight savings and increased strength to combat the extreme stress loads exerted on the blades during operation. Carbon fiber, however, is conductive and more prone to be struck by lightning. Without proper protection, they are susceptible to severe damage and catastrophic failure.

Want more information on lightning strike protection for composite wind blades? Download our free paper.