Filtration and separation are key criteria for industries that produce semiconductors, process chemicals, and pharmaceuticals, or systems that control gas or liquids. Dexmet custom manufactures MicroGrid® and PFOA-free PolyGrid® materials in a multitude of open area configurations with controlled pore sizes to provide more consistent particle removal, flow rates, and pressure drops for your filtration application.

Expanded MicroGrid® can be used for either primary filtration applications to protect critical downstream components or as internal cores to support the filtration media. Typically, expanded metals are used for these applications because they require strength and operate at higher pressures.

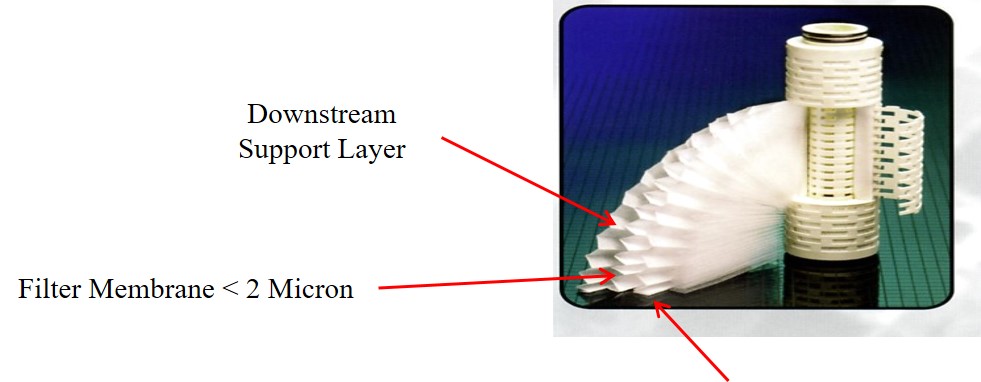

Expanded PolyGrid® materials are used primarily as membrane support materials on the upstream and downstream of the membrane. Expanded polymers can be used as a primary filter but typically for lower pressure air or gas applications.

Dexmet produces PFOA-Free PolyGrid® expanded Fluoropolymers. PFOA (Perfluorooctanoic Acid), widely used as a polymerization surfactant in making fluoropolymers including PTFE, PFA, and FEP, has fallen under scrutiny by the EPA and FDA for its potential toxicity and widespread presence in the environment and human population. Utilizing Dexmet's fluoropolymers will ensure that your application meets any new EPA or FDA requirements while being safe to the environment.

Dexmet custom manufactures PolyGrid® high performance materials from fluoropolymers and thermoplastics with controlled pore sizes to provide proper particle removal with more consistent flow rates and pressure drops for your filter application.

Excellent membrane support, primarily used for separation and backing materials in pleated filtration designs

Pore size starting at 75 microns (.003”) with base material thickness down to .025 mm (.001”). Widths to 610 mm (24”)

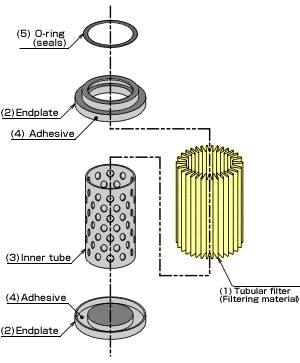

Filters that are designed to remove fine particulate (less than 0.1 mm) frequently employ non-woven filter media that requires mechanical support within the filter body. The support must provide adequate strength while not significantly reducing the flow of the fluid to be filtered.

Dexmet specializes in offering expanded fluoropolymers and thermoplastic materials that are often difficult to obtain in either extruded or woven product.

Specialized fluoropolymers include:

PTFE, PFA, FEP, ECTFE

High-performance thermoplastics include:

PEEK, Polysulfone

Performance Features:

Filtration Rating:

Backpressure:

Flow backpressure results from the “percent open area” and the degree of particulate build-up on the media surface. Choose a material that will more than withstand the full pressure drop across a blocked surface area.

Filter Strength:

Ultimate strength is controlled by material selection, thickness, percent open area

MicroGrid® precision expanded materials used for primary filtration or internal core applications can be manufactured from a variety of metals, thicknesses and opening sizes to ensure strength, particle removal and media compatibility

Dexmet expanded metals are used in filters as both filter media (for coarse particles) and internal support cores for fine filter media (especially non-woven fabrics). Dexmet can provide a wide variety of metals and geometries to exacting specifications. With so many materials and configurations, Dexmet has the right material to maximize filter efficiency and usable life, while reducing internal corrosion and other failure modes.

Filters (or pre-filters) that are designed to remove large particulates (over 0.5 mm in diameter) must be made to withstand impact stresses as well as fluid pressure. “Open” (expanded, perforated or woven wire) metal foils are frequently used for this function because they can be easily formed for the specific application.

Stainless Steel, Aluminum, Nickel Alloys, & Carbon Steel (FE).

Dexmet has the capability to expand all ductile metals.

For information on the advantages and characteristics of MicroGrid® primary filtration media and internal core support materials, download this free