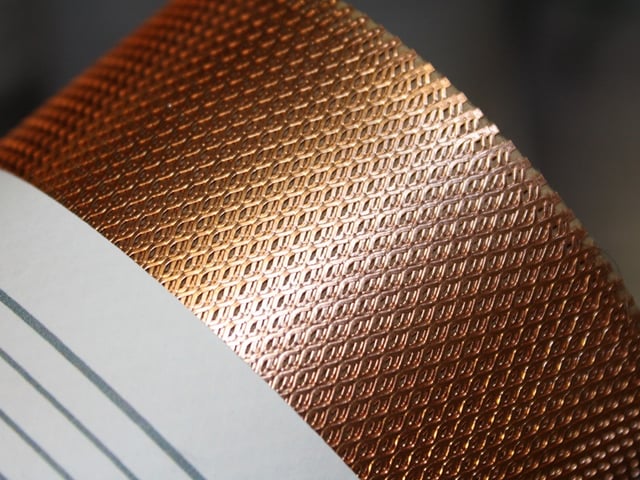

Lightning Protection - Aerospace

Copper and Aluminum Expanded MicroGrid® material made to protect composite surfaces and structures against lightning strikes for both the Aerospace and the Wind industries.

- Thin, Lightweight & Flexible

- Single unit structure for more consistent conductivity over larger surface areas that won't fray or unravel

- Capable of withstanding a Zone 1 Strike of 200,000 amps

With over 100 different configurations that meet specific applications, minimizing weight and maximizing conductivity, Dexmet has the precise material for your application. If not, we'll develop one that meets your exact requirements.

Lightning Protection - Wind Energy

As the requirement for wind turbines to produce more power, wind blade designs are becoming larger to meet these higher output demands. As they become larger,weight becomes an issue and designers are starting to incorporate more carbon fiber into the blade construction. Through the knowledge and history in carbon fiber aerospace applications, Dexmet has been called upon to help determine the correct configurations and materials for lightning protection on these hybrid carbon fiber/composite blades. Configurations are more conductive and configured to withstand multiple strikes and therefore are slightly heavier than materials required for Aerospace.

Primary Battery Electrodes

Dexmet has been integral in many battery designs in advanced battery applications. Expanded metal for non-rechargeable, primary batteries anodes and cathodes is the right choice for these electrodes to optimize performance. The battery chemistry determines the alloy used, while the active material composition determines the optimum mesh geometry. With Dexmet's highly configurable expansion process, configurations can be dialed in to meet conductivity, weight or active material density to maximize battery performance.

Typical Battery Applications:

- Lithium Thionyl Chloride (Li-SOCl2)

- Manganese Dioxide (MnO2)

- Sulfur Dioxide (SO2)

- Zinc Air

Secondary Battery Electrodes

Dexmet ultra-thin expanded MicroGrid® foils are engineered for rechargeable advanced batteries, supercapacitors and lithium ion applications. With material thicknesses down to 25 micron (.001") and open areas that range between 50%-75%, our electrode materials are suitable for many cylindrical and pouch cell applications. The expansion process allows us to control the thickness, weight, open area and conductivity.

Typical Battery Applications:

- Advanced Lithium Ion

- Lithium Polymer

- Nickel Metal Hydride (Ni-MH)

- Zinc Air

MicroGrid® is commonly implemented as anode and cathode current collector screens, and as support structures for active materials.

Electrolyzers & Fuel Cells

Dexmet materials are utilized in PEM and SOFC fuel cells as current collector electrodes, catalyst substrates, and gas diffusion layers. Fuel Cells typically use expensive materials like niobium, zirconium, titanium and nickel to counteract the corrosive environment inside the cell to maximize the cells lifespan. The expansion process is the most cost effective way to produce an open area product from the expensive materials. Dexmet helped create one of the first uses for expanded materials in an electrolyzer for a PEM fuel cell over 40 years ago. Dexmet sees itself as a partner to it's many clients and is at the forefront of development for open area products in fuel cells. We understand the technology and can help our clients bring their products to market.

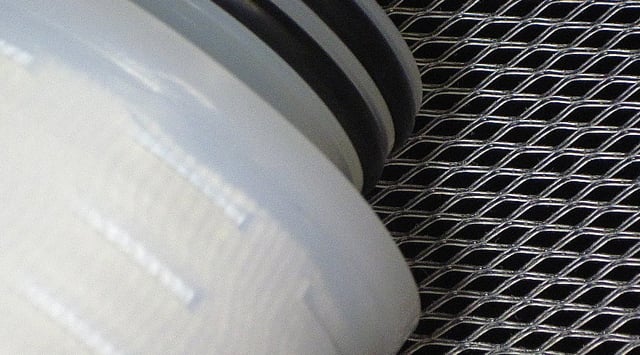

Filter Media and Media Support

Dexmet can provide a wide variety of MicroGrid® metals and PolyGrid® polymers with geometries to exacting specifications for either primary filtration or as media support materials for fine particle cartridge filters. It is important to choose the right material to maximize filter efficiency and lifespan, while reducing internal corrosion and other failure modes.

- Low Fluid Flow Resistance Feed & Drainage Layers

- Filtration Enhancing Membrane Support & Separation Backing

- Assures Media Integrity & Pleat Spacing Under Dynamic Flow

EMI Shielding

The Dexmet MicroGrid® EM series of expanded metal foils (EMFs) are effective materials for shielding against electromagnetic interference (EMI). They are electrically continuous and, unlike knit or woven meshes, exhibit consistent, predictable conductivity and shielding effectiveness over a wide range of frequencies.

Typical Applications:

- Shielded Enclosures

- Gaskets

- Ventilation Screens

- Cable Shielding

- Laminated Structures

Automotive

Expanded metal and hi-performance polymers can be utilized in a wide variety of automotive applications from high temperature gaskets to greaseless bushing, primary filter screens to speaker grills. With so many combinations of materials and configurations, Dexmet will the solution for an open area product in your automotive application

- Design flexibility and strength

- Durability and malleable, able to be used in various automotive applications

- Cost-effective and material can be easily coated

Industrial Applications

The light weight and strength of standard expanded metal and plastic make it a popular material for a wide variety of commercial and industrial applications. Expanded materials are the "Swiss Army Knife" of open area products. The ability to easily change parameters of the material to dial in exact properties on strength, open area and weight make it perfect for applications from medical devices to heat exchangers.

Some of the more common uses for Dexmet expanded metals and polymers are for Thermal Management, Heating Elements, Medical Devices and Cathodic Protection.