Expanded foils have been Dexmet's calling card for over 70 years. No other manufacturer can match the consistency and uniformity of Dexmet's open-area products.

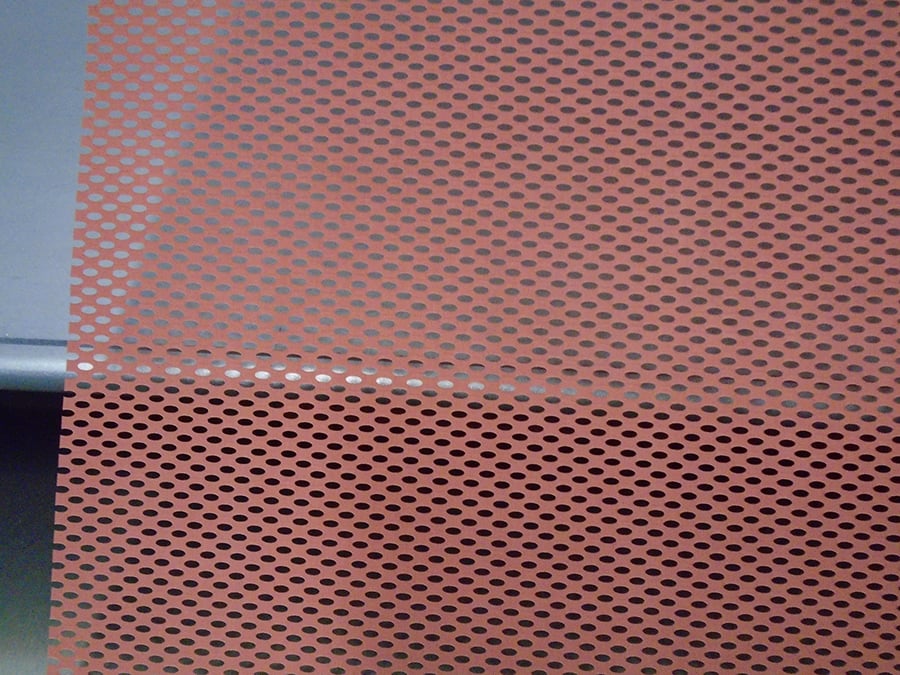

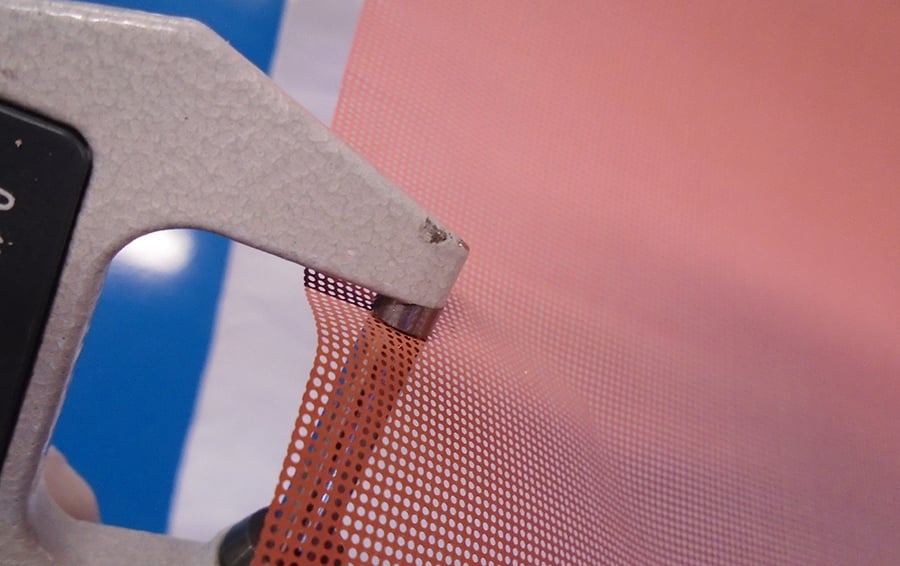

But there are applications where expanded foils meet their limits... The relentless push toward thinner, lighter products has led the company to expand its expertise into an adjacent, complementary technology: Perforated foils.

The precision, consistency, and volume production capabilities of Dexmet expanded products are now available in perforated format. Users in the aerospace, power storage, and filtration industries now have a further range of open-area foils to choose from. Delivered right, and delivered on time.

From 140µm to as low as 15µm. Cu, Al, plastics; more materials to be added

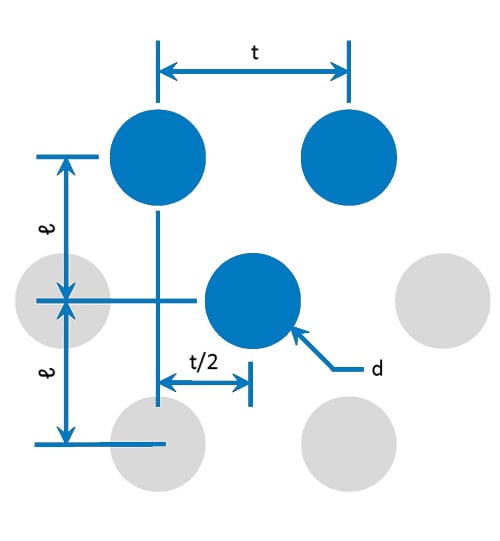

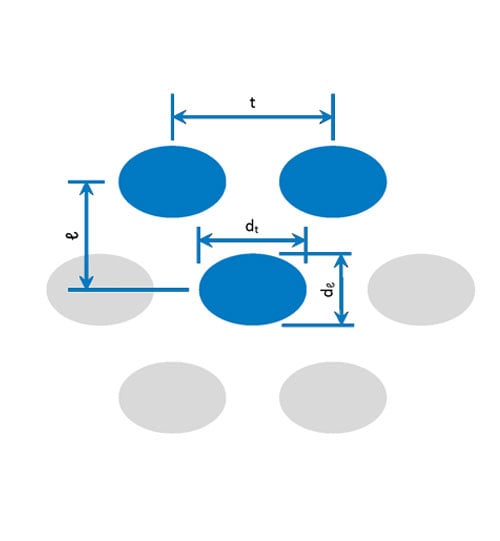

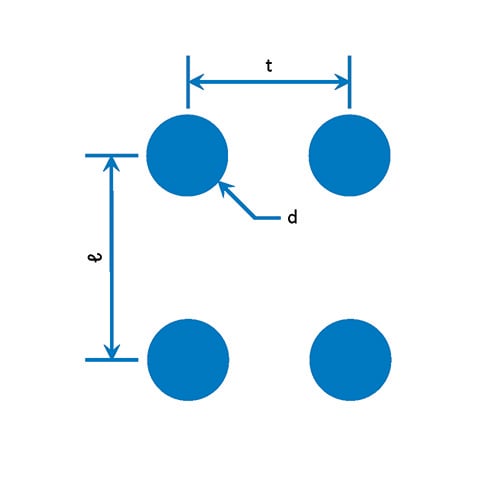

0.5 to 5mm - round, square, elliptical

From >30% to <<1%

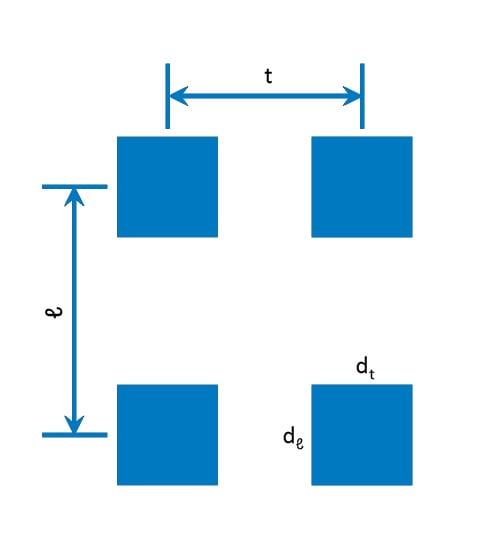

Below is a small subset of the hole sizes and geometries available from Dexmet

Dexmet is able to perforate in a number of materials, shapes, and patterns. However, there are factors that influence the cost of perforated materials: material cost, the pattern level of difficulty (hole size vs. material thickness, perforation end patterns, tolerances, and the quantity ordered).

It is always best to contact Dexmet so that we can recommend a product that is suitable for your application, or help in developing a perforated material that can fulfill your needs.

Dexmet specializes in open area products for appliances, audio, automotive, chemical, electrical, filtration, medical, power generation, and aerospace.

To learn more fill out the contact sheet below, or if you wish to subscribe to our blog, click on the button below to keep abreast of all new developments at Dexmet.